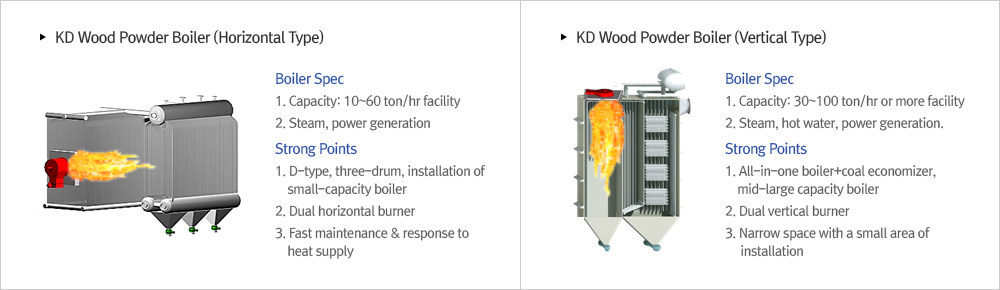

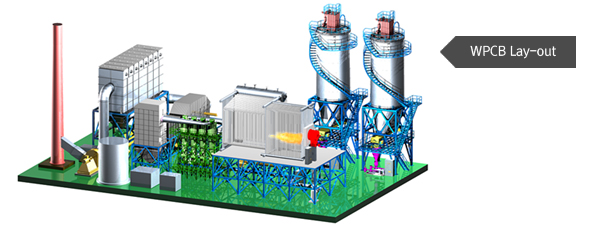

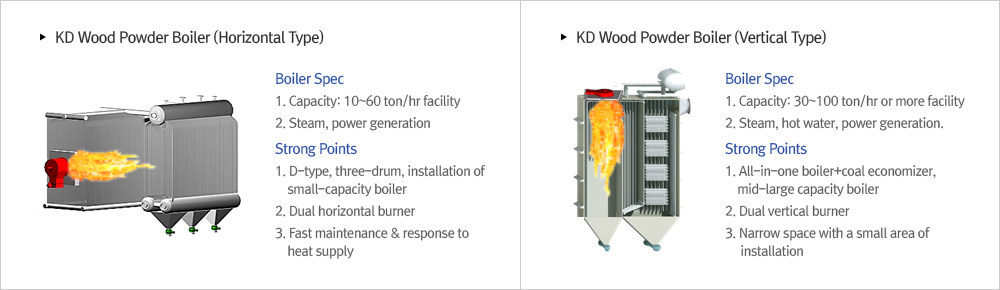

- Structure and Strengths of the WPC Boiler

- The structure of the KDE WP Boiler has a ‘water wall’ in the combustion chamber. The inside of the combustion chamber and the boiler itself minimizes and solves the generation of ash and dust while operating. The heat efficiency is maximized to 90~95% compared to other solid fuel boilers.

- The KDE WP Boiler injects secondary hot gas and cold air inside the combustion chamber and delays the temperature decrease and the residence time of gas in the combustion chamber, preventing low-temperature corrosion and reducing inside some parts of the boiler the amount of Nox generated during combustion.

- Features of the WPC Boiler

- Excellent capacity for heat load variation compared to other solid fuel boilers (full system automation available).

- Advanced compared to other solid fuel boilers (indirect heating method): the direct heating combustion method provides high operational performance and heat efficiency.

- Complete combustion with optimal combustion chamber; convenience in maintenance, with less ash compared to other solid fuel boilers.

- Dual burner is usable as emergency alternative fuel (operational safety ensured compared to other solid fuel).

- Full closed system of fuel supply and facility operation to treat ash and dust due to environmental problems.

- Immediate detection and auto-extinguishing when there is a spark in each section of the facility as preventive measures against dust explosion while using powder fuel.

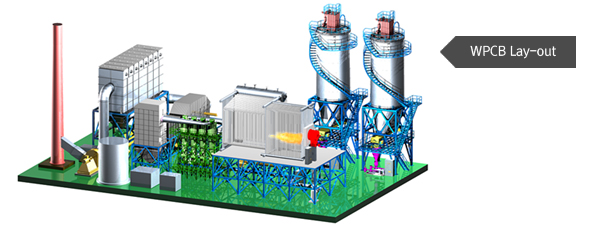

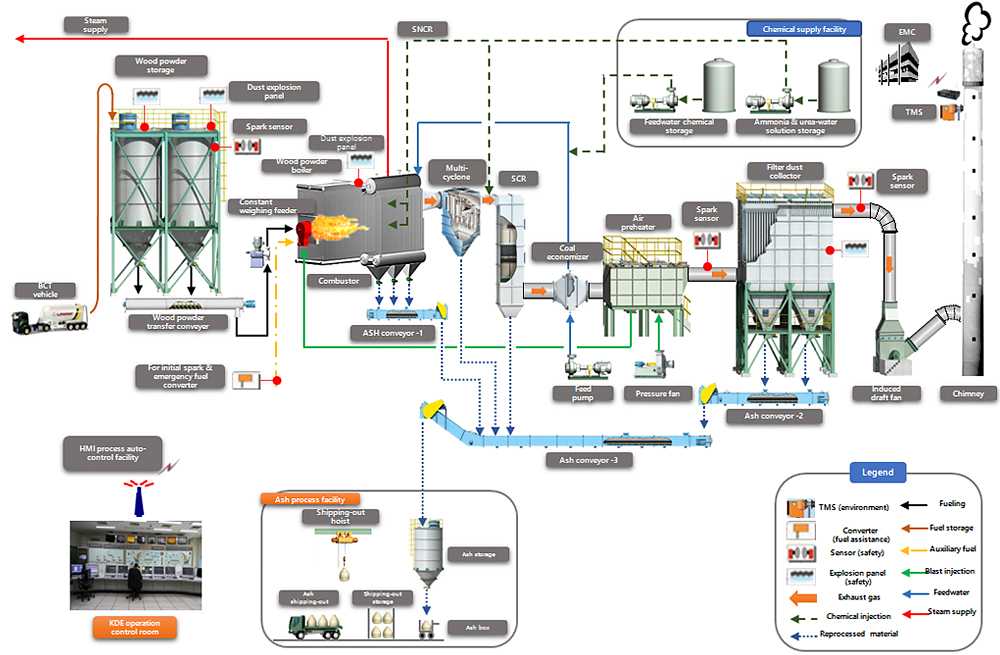

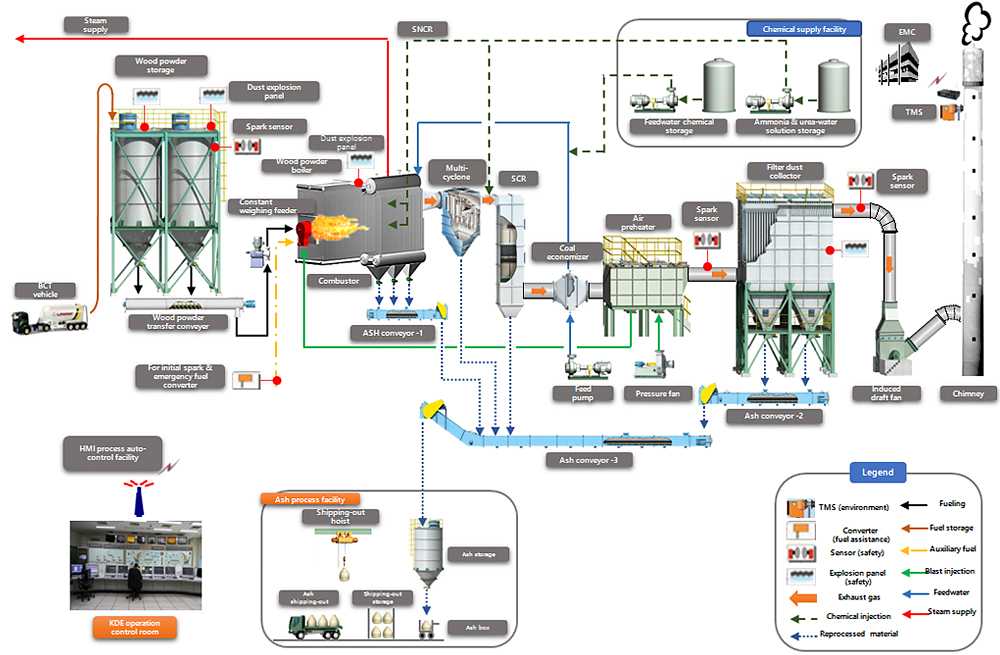

WPCB Flow Diagram

Composition and Function of WPCB Facility

-

Atmospheric environment field

Easy management of atmospheric environment discharge below the regulations can be achieved by using wood biomass fuel.

-

Eco-friendly facility

The latest environment technology (de-NoX and dust) and TMS ensures to keep emission level within the legal limit.

-

Preventive measures of explosion

Immediate detection and auto-extinguishing when there is a spark inside the silo or dust collector.

-

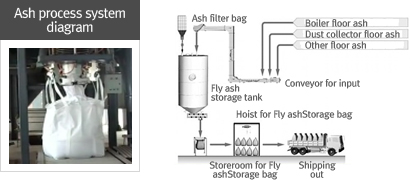

Ash process measures

Ash generated after combustion is transferred by screw conveyor, collected en bloc, stored in the ash box (ton bag), and processed.