- Structure and Strengths of the NWP Boiler

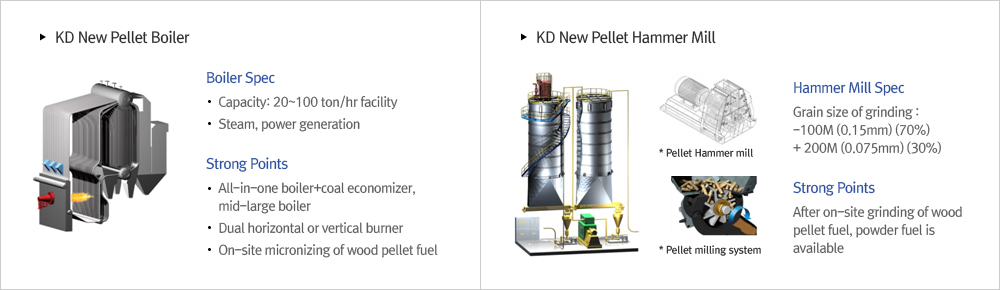

- The KDE NWPB Boiler can grind wood pellet fuel on site, unlike the previous wood pellet boiler, and can save fuel.

- The KDE NWPB Boiler separates itself from the previous wood pellet boiler with improved facilities in reducing environmental and air pollutants, in addition to a guaranteed operating life and performance.

- The KDE NWPB Boiler has an all-in-one coal economizer and air preheater, improving on the efficiency and load variation of the previous wood pellet boiler. The secondary injection of hot gas and cold air in each section of the combustion chamber solves the conventional clinker, ash, and dust generated when pellet fuel is combusting and can minimize the generated amount of Nox.

- Features of the NWP Boiler

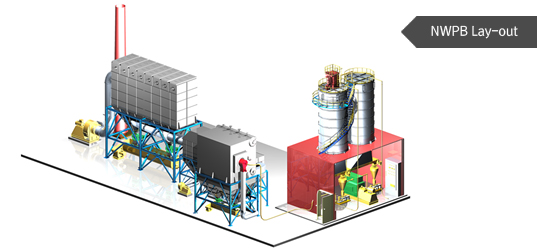

- On-site micronizing and use compared to conventional wood pellet fuel (storage of powder fuel using pellet hammer mill).

- Preventive facility against dust explosion arising during micronizing (explosion-proof milling room and preventive device installed).

- Shipping-out and transfer facility of wood pellet and ground wood powder (closed air transfer for fuel feed).

- Advanced compared to other solid fuel boilers (indirect heating method): the direct heating combustion method provides high operational performance and heat efficiency.

- Dual burner is usable as emergency alternative fuel (operational safety ensured compared to other solid fuel).